We provide advanced solutions to meet the needs of both single production and mass-production clients.

Backed up by decades of experience, we are prepared to solve any special industrial automation task. We provide advanced solutions to meet the needs of both single and mass-production clients. We will help you with design, software development, installation as well as maintenance for your custom device or complete system project. Utilizing our experience and expertise, we will also provide you with consulting services enabling you with the all the essential information to make an informed decision on improvement issues.

Our portfolio also includes:

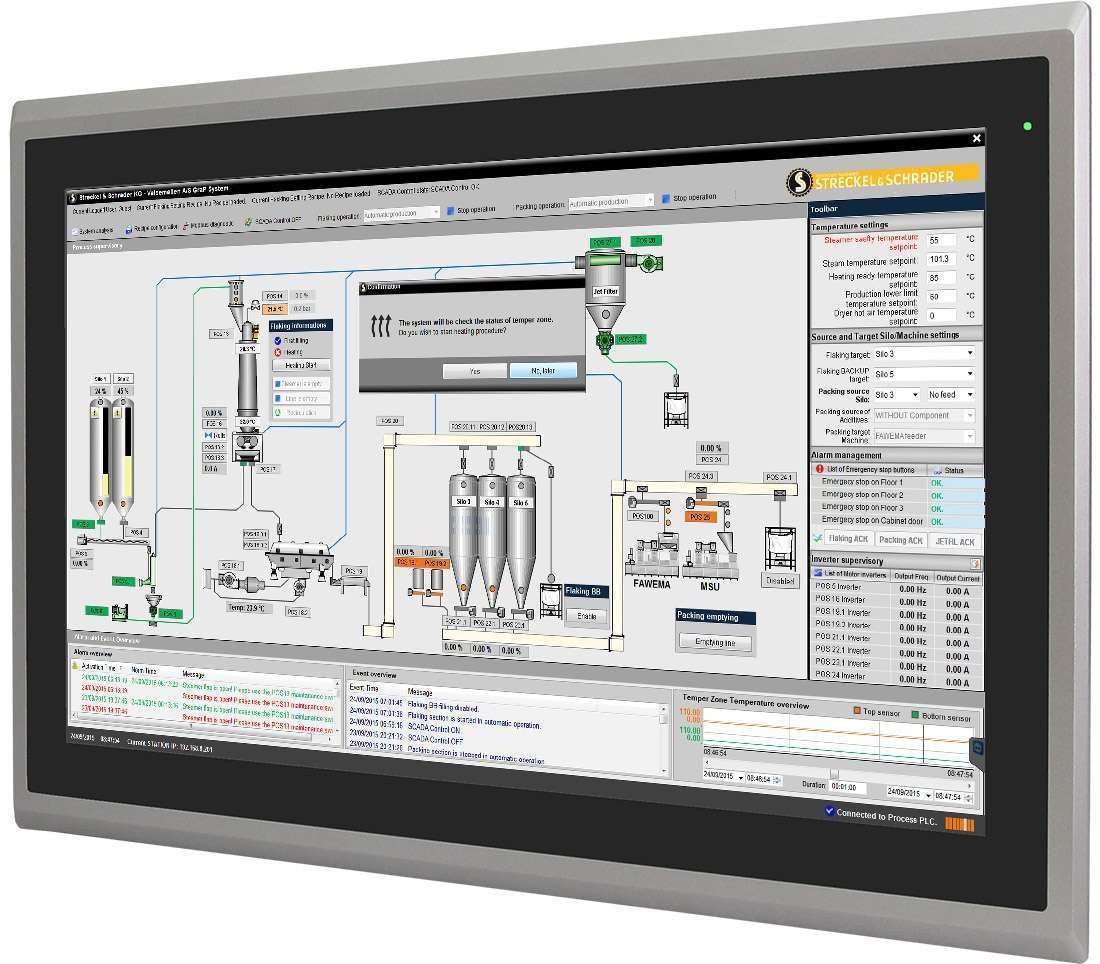

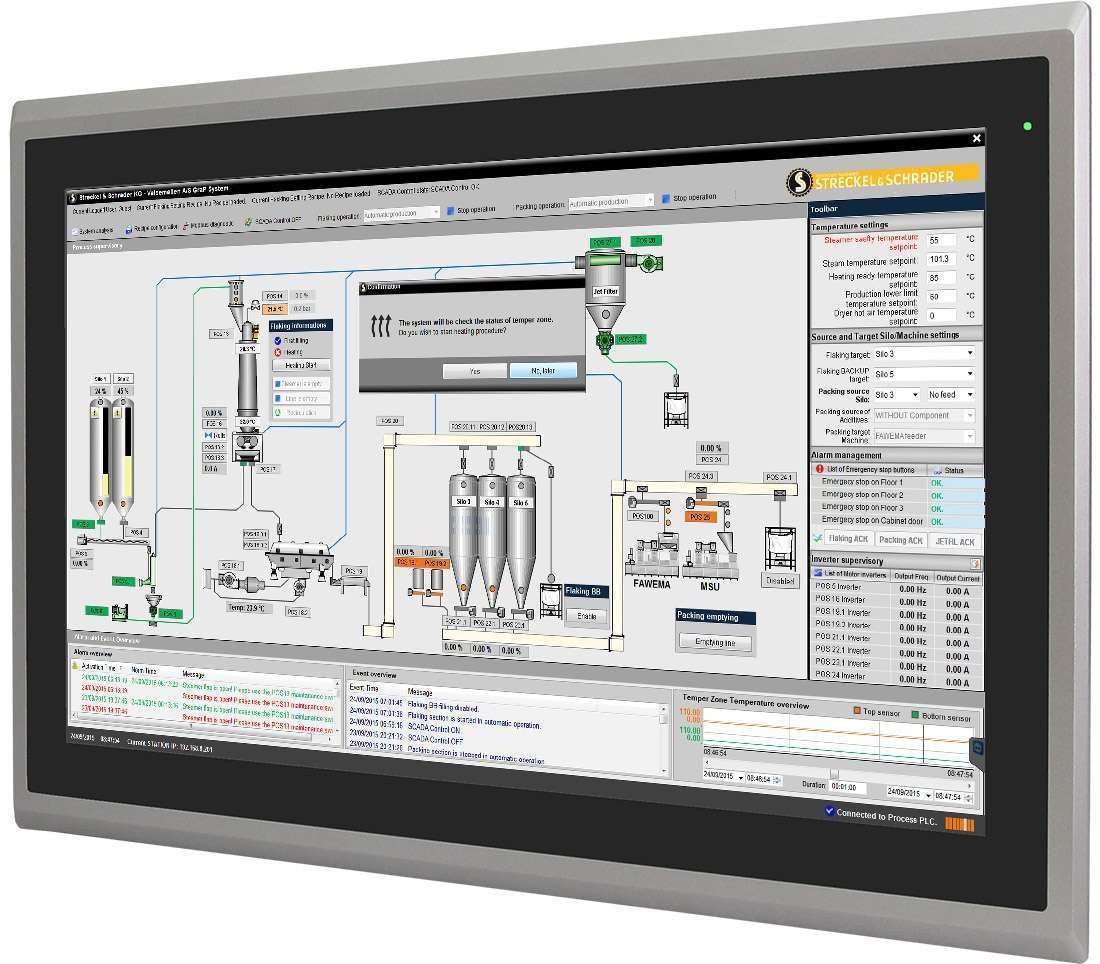

- full industrial implementation and automation (PLC, SCADA system, access control systems),

- measurement technology implementation (volume, level, dissolved oxygen, pH, COD, etc),

- full automation and implementation of wastewater plants and systems,

- full electrical and control engineering design of grain processing systems (Grap) including automation with logging, alarms and remote PC

- monitoring functionality. Small and large livestock farms, automatic lighting, automatic climate control, etc.

With many years of experience in the automotive industry, we provide you with high quality design, construction and programming services for industrial automation and control technology.

Any questions about automation and control engineering?

FAQ

What does industrial automation mean?

Industrial automation is the use of control systems, such as computers or robots, as well as information technology to manage various processes and machines in industry instead of using human resources. This is the second step beyond mechanization in the field of industrialization.

What is included in industrial process automation?

Process automation involves the use of sensors, drives, computing, and software development to help plants and factories in industries such as automotive, mining, food, or even waste management create more efficient and safer processes.

What automation options are there (types)?

In manufacturing, three types of automation can be distinguished: fixed automation, programmable automation and flexible automation. In this order, between large-scale set production and small-series flexible production.

What is PLC, HMI, SCADA?

SCADA systems are combinations of many systems, including sensors, RTUs or remote terminal units and PLCs. A PLC (Programmable Logic Controller) is a unit containing an automation program that manages the outputs and inputs of the system. The HMI or “Human Machine Interface” unit on SCADA can monitor and control anything that is connected to it. In practice, it usually means a touch screen or interface. In summary, the HMI may be part of the SCADA, but the SCADA may not be part of the HMI.